EN420 is a European PPE glove standard that all types of safety gloves must earn before they can earn any other standard. However, this is not a standard that gloves commonly list among their features because it consists of relatively common-sense specifications. This does not mean that this standard isn’t important, in fact, it is the opposite. Many of the requirements needed to make the grade are why the glove has made it to the market.

EN420 Explained

General Requirements and Test Methods

First and foremost, EN420 safety gloves have to be safe and comfortable to wear. In order to accomplish this the gloves must meet the following requirements:

- The gloves must have been made to provide the protection they are intended for

- The edges and seams must not cause any harm to the user or reduce the glove’s performance

- The gloves must be easy to take on and off

- The material must not harm the user (natural rubber gloves should be tested on extractable proteins to ensure they do not cause allergic reactions)

- The pH value of the gloves should be between 3.5 and 9.5 (PH is measured on a scale of 1 to 14, with 1 being strongly acidic and 14 being strongly alkaline)

- In leather gloves, Chromium (VI) content should be below 3mg/kg

- The protective quality of the glove must not be affected, nor should the level of performance be reduced when the washing instructions are followed correctly.

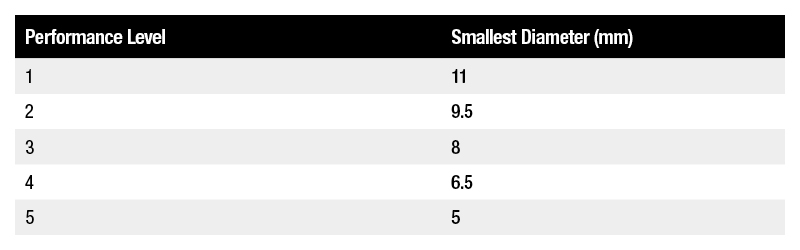

- The gloves must allow as much finger mobility as possible. Dexterity is tested by picking up pins with a gloved hand, with the pin becoming smaller through each round of tests. Dexterity levels range from 1 to 5, with 5 being the most dexterous

Water Penetration

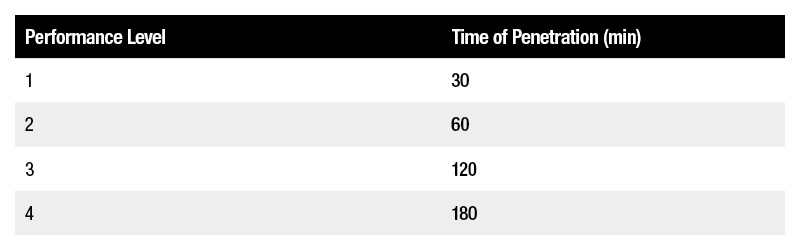

EN420 also outlines requirements for resistance to water penetration. This, however, is not a compulsory test. It is only assessed if necessary, according to the intended use of the gloves.

For leather gloves, a sample of the leather is tested for penetration. In this test, the sample is clamped to circular clamps and flexed in water, known as a penetrometer test. The leather continues to be flexed until the water begins to penetrate from the outside of the sample to the inside. The results of this test are recorded as the number of minutes to penetration.

Gloves that are tested for water penetration under EN420 are defined with a level of 1 to 4. Level 1 is the lowest penetration level (penetration occurs within a 30-60 minute period) and level 4 is the highest penetration (there is no penetration before 180 minutes).

Water Vapour

The water vapour transmission and absorption standard under EN420 states that protective gloves should allow the transmission of water vapour to aid in wearer comfort by enabling perspiration to escape from the glove. This test is assessed by clamping the material of the glove in the mouth of a bottle containing solid desiccant and is kept in a rapid current of air. Keeping the desiccant in motion circulates the air within the bottle. The bottle will increase in weight as the desiccant absorbs moisture from the air that has transmitted through the glove material. These results are expressed in units of mg/cm2.h. The standard states that, if required, the glove material shall allow a water vapour transmission of 5mg/cm2.h.

This test is not relevant for moulded rubber or plyometric gloves as they will not allow water transmission. In these cases, the construction or material of the glove should be absorbent to reduce the effects of perspiration. This is assessed by clamping the glove material over the mouth of a sealed container over the water. During the test, the water vapour will be absorbed from the air within the container. The results from the test are expressed in mg/cm2. The standard states that, if the glove material is to exclude water vapour transmission, it should have a water vapour absorption of at least 8mg/cm2 when tested for a period of eight hours.

Marking Requirements

Under EN420 standards each glove must be marked with the following:

- The name of the glove manufacturer

- The designation

- The size

- The CE Mark (CE markings are used to certify that the gloves are manufactured to the European Economic Area standards, indicating that the product conforms with these health, safety and environmental standards)

- Appropriate pictogram

Instructions For Use RequirementsThe EN420 pictogram (as shown on the left) is used to communicate that the instructions for use are included within the gloves' packaging. These instructions outline the build and applications of the glove. |

According to EN420, the instructions for use must include the following information:

- The glove and size designation

- The name and address of the manufacturer (or representative)

- An explanation of the pictogram and glove marking

- Reference to the EN standard that the glove has been tested against (for example “EN388 for protection against mechanical hazards” will be shown next to the pictogram)

- Instructions for use and relevant limitations

- Storage and care information for the glove

- Guidance on how to dispose of the glove after use

- Information on substances in the glove that may cause allergic reactions

- Warnings relating to any medical or thermal risks/chemical hazards

- Information on which chemicals have been tested and up to which level (this applies to EN374 chemical protection gloves)

Once all these requirements are met, the glove can then progress to be tested against other standards according to what the glove is going to be used for such as mechanical hazards (EN388), high heat (EN407), chemicals (EN374), cold (EN511) and radioactive contamination and ionising radiation (EN421).

Browse our range of gloves here

If you’re not sure about any of the information you’ve read here, get in touch with the experts at ATOM Safety for any of your PPE and safety-related questions.