It is essential to be equipped with the correct personal protective equipment (PPE) when dealing with hazardous materials. Coveralls are one-piece, loose-fitting suits that offer protection against outside contaminants over a large area of the body. Coveralls are essentially a full body protection suit, generally worn over the top of personal clothing, and can protect workers against a number of hazards, including hazards of a chemical, mechanical, thermal or biological nature. Coveralls can be made from numerous materials, offering differing resistance to many workplace hazards. Coveralls protect the body from the ankles to the wrists and disposable coveralls feature hoods to protect the head. Coveralls are required across a range of varied industries such as agriculture, petrochemical, food, mechanical, emergency response and other labour-intensive industries.

Coverall Standards

Coveralls are tested according to AS/NZS4501.2 (EN ISO 13688) standard. This standard specifies the performance requirements of protective clothing across various factors including ergonomics, innocuousness, size designation, ageing, compatibility and marking of protective clothing and the information that needs to be supplied by manufacturers with the protective clothing. The standard ensures that protective clothing;

- Does not negatively impact the health or hygiene of the person wearing it

- Accommodates the movement and positioning of the wearer so that no part of the body is exposed to potential hazards during use

- Is comfortable to wear

- Clearly states the number of times it can be worn to ensure ageing through wash and wear does not expose the wearer to potential hazards

- Sizing is clearly visible

- Is marked with correct information that is in an appropriate language is legible and will not fade with wear

ISO 13688:2012 is not intended to be used on a standalone basis and instead should be applied in conjunction with other standards that contain specific requirements for the performance of protective clothing.

Coveralls are also tested according to EN 14126, the standard which determines the performance requirements of protective clothing against infective agents. This standard focuses on the medium containing the bacteria or other infective agents, such as a liquid, aerosol or solid particulate and does not define performance requirements for specific infective agents. The standard consists of five tests which are conducted against fabrics only, and not the completed garment. This needs to be considered when selecting appropriate protective clothing for the workplace as hazards may be small enough to enter the suit through the opening of sewn seams for example, so welded seams may be the most suitable option. The 5 tests are;

- ISO 16603: Resistance to penetration by blood and bodily fluid using synthetic blood. This is a screening test that determines what pressure the ISSO 16604 should be conducted under.

- ISO 16604: Resistance penetration by blood-borne pathogens using a bacteriophage

- EN ISO 22610: Resistance to wet microbial penetration by biologically contaminated liquid

- ISO/DIS 22611: Resistance to liquid aerosol penetration by biologically contaminated liquid aerosols

- ISO 22612: Resistance to penetration by biologically contaminated dry, solid particles

Fabrics are given a class rating dependent on their performance in each of the above tests and how long it takes for the infective agent to penetrate the fabric, which can be found on their individual data sheets; the higher the class the higher the level of protection. If the fabrics pass one of the above tests, they will be certified as EN 14126.

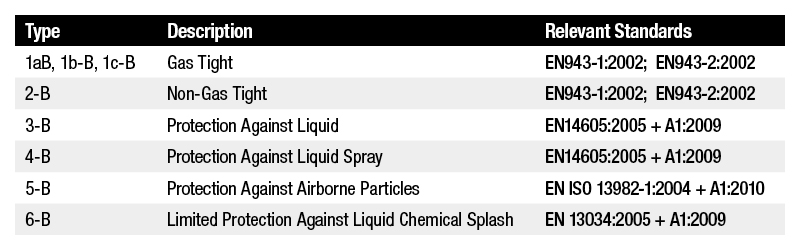

Protective suits which have been constructed with EN 14126 compliant fabrics will then need to meet the requirements of their “Type” standard. The table below outlines the standards for each type of coverall. Coveralls that have met the standards of their Type, as well as the EN 14126 standard, will be marked with the appropriate Type as well as “-b” which indicates that it is certified EN 14126.

Type Classifications

As well as the above testing standards, coveralls are also subject to rigorous testing to determine their ‘Type’. A coverall’s Type indicates its suitability for certain environments and its level of protection against different hazards. Tests must comply with the above standards and will measure the coverall’s performance against a number of variables including:

- Abrasions

- Cracking

- Tensile strength

- Liquid repellence

- Tear, puncture, chemical, ignition, spray and aerosol resistance

Dependent on their performance under these testing conditions, suits are classified into Types, ranging from one to six.

The different types of coverall are:

|

Type 1: Gas Tight Type 1 coveralls are gas-tight and offer the highest level of protection against workplace hazards. Type 1 suits are completely sealed against the environment, protecting the wearer against any chemical contamination in the form of either liquid or gas, as well as aerosols and solid particles. They are subjected to a test that ensures they are gas-tight and are re-tested regularly. These coveralls are used in highly hazardous industrial environments and by emergency workers. |

|

|

Type 2: Non-gas Tight Type 2 coveralls are non-gas tight. They prevent dust, liquids and vapours from entering the suit but must retain a positive pressure to do so. Type 2 suits, like Type 1 suits, are used in highly hazardous industrial areas and by emergency responders. |

|

|

Type 3: Protection against Liquid Type 3 coveralls protect the wearer against liquids. They are able to withstand strong, directional jets of liquid. They are tested by having strong jets of liquid blasted at weak points on the suit (seam joins, zip fastenings). Because of these testing requirements, suits of this nature require a barrier fabric and sealed seams. Type 3 suits have a subcategory of classes which is determined by testing their breakthrough time; the amount of time it takes for liquid to enter the suit. Only a minuscule fraction of liquid is permitted to enter before it is deemed a failure. Lower end suits, Class 1, have a breakthrough time of 10 minutes with Class 6 suits on the higher end of the spectrum lasting for over 6 hours without liquid penetration. |

|

|

Type 4: Protection against Liquid Spray Type 4 coverall suits offer protection against liquid spray and the saturation of liquids. Testing of this Type of coverall is similar to the testing carried out on Type 3 suits, however, in this test, the liquid is applied to the suit using less pressure and is then allowed to pool on and saturate the suit. During the test, the garment is subject to a shower of liquid over one minute while the subject wearing the suit rotates on a turntable. As with Type 3, this type of coverall requires welded seams so that no liquid can permeate through the suit and onto the wearer. |

|

|

Type 5: Protection against Airborne Particles Type 5 coverall suits protect the wearer against dust and dry particles. Type 5 coveralls are tested by having a subject perform exercise on a treadmill while a spray cabin is filled with dust. Particle counters inside the suit then calculate the inward leakage (the amount of dust that enters the suit). They are suitable for industrial cleaning, site preparation and handling insulation. They are also suitable for asbestos and silica protection. When dealing with hazardous materials such as asbestos and silica dust, it is important that workers have completed risk assessments and are wearing the correct clothing to avoid the risk of contamination. These are used once only suits as decontamination cannot be guaranteed. Ansell is a leading brand in the safety space and manufactures quality asbestos suits to keep workers protected on site. |

|

|

Type 6: Protection against Liquid Chemical Splash Type 6 coveralls protect the wearer against light spray and splashes. They are similar to Type 3 and Type 4 suits however they are tested with a light spray of liquid which is not permitted to build up on the suit. In this instance, the subject rotates on a turntable as four nozzles spray liquid onto the suit and afterwards the inside of the suit is checked for any penetration. Dependent on the testing criteria and the amount of liquid inside the suit, it will be classed as a pass or a fail. They offer the lowest level of protection and should only be worn in low-risk environments. |

Coveralls with Multiple Types

Coveralls may also be approved for more than one Type. Multiple Type numbers mean the coverall is a suitable form of protection against a variety of hazards and has met the criteria across multiple tests.

For instance, coveralls that are rated as Type 5/6 have passed the testing criteria for both Type 5 coveralls and Type 6 coveralls. This means they offer protection against all the hazards both coveralls protect against. Type 5/6 coveralls are usually used by asbestos removalists but can also be used by workers in the wood and plastic processing industries and general manufacturing and maintenance. The same applies to Type 3/4 coveralls. They protect against hazards from both Type 3 and Type 4 coveralls. Type 3/4 coveralls can be used for chemical protection and oil spill cleanups.

Coverall Materials

Coveralls can be made from a range of different materials which contribute to their performance as a protective barrier against hazardous materials. Woven fabric, for instance, is not a suitable material to construct a coverall with as gaps present in the material structure leave space for hazardous material to permeate the suit. Non-woven fabrics, with a much denser structure, are therefore more desirable when designing protective coveralls.

Polypropylene (PP)

Polypropylene coveralls are constructed from a non-woven fabric but are usually not dense enough to provide adequate protection to the wearer and are more suited to conditions where particles of a non-hazardous nature are likely to come into contact with the wearer or their personal clothes.

Spunbound-Meltblown-Spunbound (SMS)

Coveralls made from SMS are constructed using 3 layers of polypropylene fibres. The outer spunbound layers give the coverall its physical strength. The middle fibres are then meltblown into a dense structure that is able to filter out chemicals and dry particles and is what gives the suit its protective qualities. Suits made from this material are relatively comfortable and breathable and offer a high level of protection.

Microporous Film Laminate (MPFL)

MPFL is a two-layer fabric that provides adequate protection. The protective layer of the suit is constructed from microporous polyethylene film which is bonded to a layer of spunbound polypropylene. The film does have the potential to vary and is, therefore, unable to provide uniform protection. It is also located on the outer layer of the suit which makes it susceptible to physical impact which may disrupt its protective capabilities.

How to Wear Coveralls

It is important that coveralls are worn correctly as, if worn improperly, they are not an effective form of protection against workplace hazards. The steps below outline the correct way to wear coverall suits to ensure optimal performance.

|

|

How to Remove Coveralls

Coveralls and any other PPE must not be removed while working in a hazardous area. Hazmat suits or protective clothing may need decontaminating once the job has been completed, through procedures such as a decontamination shower, before doffing. When it is safe to do so, the protective gear should be removed slowly and cautiously so as not to contaminate the wearer or surroundings. Rolling the work coveralls outwards down and touching only the inside of the suit is the best way to avoid contamination. Disposable coveralls should not be cleaned in an attempt to reuse them. Proper disposal is necessary, ensuring no contaminated PPE clothing is left in the work area.

Check out our range of coveralls here.

ATOM stocks a wide range of full-body protection suits including Ansell Alphatec and Microchem, and Tyvek coveralls from Dupont. If you’re not sure what type of coveralls are right for your job, contact the team at ATOM Safety.